Eddy Current Separators

It is suitable for a wide range of applications from the recovery of small non-ferrous metals to larger shredded scrap metal processes. We have a strong commitment to support our customers and provide metal separators which are the leading performers in the industry. Our equipment is designed and built to be reliable and durable in the toughest environments.

Our fast response time at all stages from enquiry to service & support ensures you have our expertise whenever you need it.

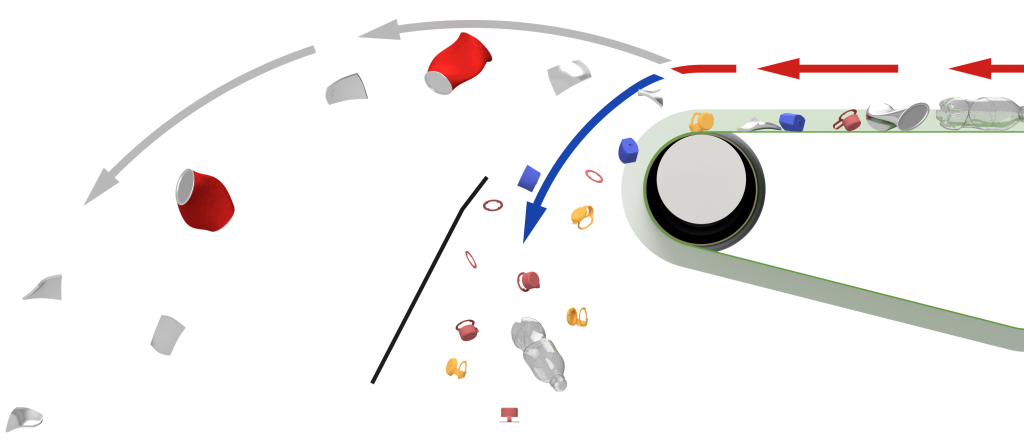

Working Principle

A high frequency high intensity magnetic rotor inside the head drum of the ECS conveyor induces a magnetic field into non-ferrous metals on the belt surface. These magnetically induced metals react with the magnetic field of the rotor which causes them to be propelled forward further than the other material on the belt. The performance is determined by a combination of flux density and frequency.

Eccentric Eddy Advantages

- Cantilevered frame design for quick conveyor belt changes (10 minutes)

- Rack & pinion splitter adjustment for simple and precise splitter placement for optimum separation

- Large access panels all around the machine allows easy maintenance access

- Compact design requires less space

- Direct drive rotor and direct drive conveyor

Sizes Offered:

- 0.6M wide

- 0.8M wide

- 1.0M wide

- 1.2M wide

- 1.5M wide

Rotors Offered:

- LT2 Rotor Assembly: 8 Pole Rare Earth Eccentric Rotor for coarse (+1") size fractions.

- ST22 Rotor Assembly: 22 Pole Rare Earth Eccentric Rotor for +1/4" to -1" size fractions.

- UHF 32 Pole Rare Earth Eccentric Rotor for fine (-3/8") size fractions.