Description

As an important support for nowadays technological development, lithium batteries are widely used in electric vehicles, electronic products and other fields. However, once used, lithium batteries will also produce a large amount of waste, bringing potential pollution hazards to the environment. We have launched a professional lithium battery recycling products and services, is committed to achieve the recycling of lithium batteries and resource regeneration.

Waste lithium batteries are valuable "urban mines", the recycling of waste lithium batteries is mainly focused on the recovery of high-value anode precious metals cobalt and lithium. Different lithium battery contain different percentage of metal, for example, the average content of lithium, nickel and cobalt in ternary batteries is about 1.9%, 12.1% and 2.3%. Copper and aluminum accounted for 13.3 % and 12.7 %, respectively, while iron accounted for 37 %. The lithium battery recycling machine of MINGXIN can separate electrode material and other materials by physical crushing method, adopting multiple screening ways , air separation methods etc.

Application

Lithium ion battery recycling solutions are used to dismantle and recycle mobile phone batteries, car batteries, rechargeable batteries, electric car lithium batteries, soft pack batteries, shell batteries, cylindrical batteries, etc. Different types of lithium batteries have different recycling procedures.

|  |  |  |

| Soft package lithium battery | Cylindrical battery | Hard shell lithium battery | Positive negative plates |

Final Product

The final products are foil, lithium cobaltate, aluminum and copper.

|  |  |

|

| Copper | Aluminum | Black Mass | Foil |

Process Flow

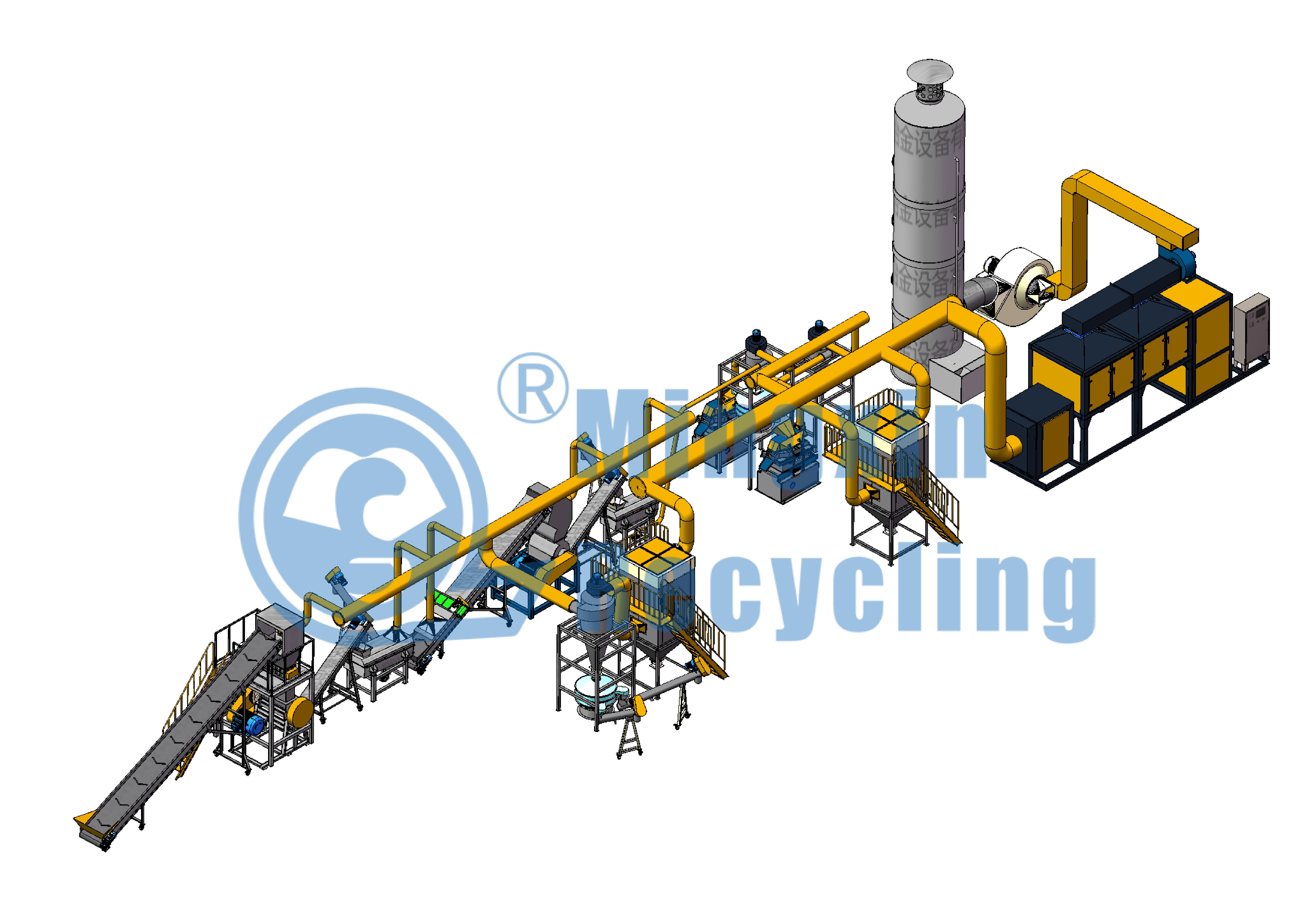

The lithium battery recycling plant consists of multiple machines working together, the following is a description of some of equipment:

- Shredder: Shredded lithium batteries into smaller pieces.

- Granulator: For the secondary crushing of shredded materials to 15mm.

- Hammer Mill: For the grinding of the crushed materials to 0-3mm.

- Separation Machine: Separate the materials after being ground.

- Cyclone Collector: Transfer material

- Pulse Dust Collector: Clean all the dust produced during the operation of the whole system.

- Classifying Screen: Screen the materials sorted by the separation machine, and screen out of large metal materials.

- Magnetic Machine: Separate Iron from the metals.

- Gravity Separator: Separate those finer materials copper and aluminum separately.

- 3D Layout